- mdi can help!

- The mdi Sales Team is standing by to help you with your order or questions about our Products. Give mdi a Call Today!

- (727) 847-4900

- Email our Sales Team

- Office Hours: 7:30 am - 7:00 pm EST M - F

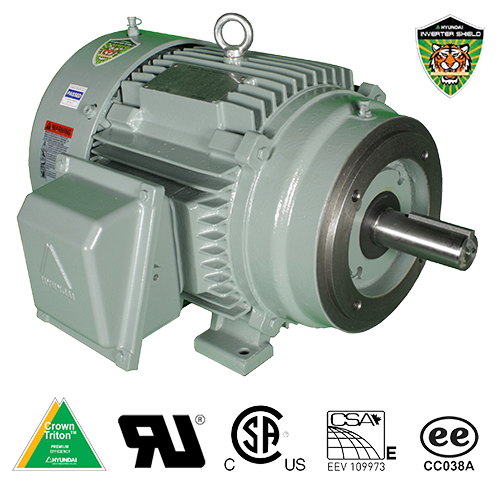

IEEE-841 C-Face

Hyundai LV Motors

Available in the following varieties:

• Rigid Base (standard)

• White Epoxy Painted

Select the following tabs to view data for the various products.

Click the model number for a model-specific downloadable PDF (when available).

-

Rigid Base Features

• 1-100 HP

• 3600 and 1800 RPM

• Single voltage, 460 volt

• TEFC enclosure

• Dual rated service factor: 1.15 for 40°C / 1.0 for 65°C

• Class F insulation with Class N varnish

• C-face - Rigid base

• Full compliance with IEEE-841, version 2009

• Meets or exceeds EISA 2007 requirements defined in NEMA MG-1 table 12-12

• 5-year warranty

• Parker Hannifin ProTech IP66 labyrinth seals on both drive-end and opposite drive-end bearings

• CSA Certified for Class I, Division 2, Groups A, B, C, D

• Inverter duty, 10:1 CT / 1000:1 VT

• Inverter shield insulation and inverter grade magnet wire meets or exceeds NEMA MG-1 Part 31 for exceptional corona and transient protection

• Class B temperature rise

• IP55 degree of protection

• NEMA design B torque

• IEEE-841 motor test report supplied with each motor

• Suitable for 50 hz operation with 1.0 service factor (1-150 HP)

- Please consult your mdi rep for 200 HP and above -

Rigid Base Technical Specifications

Model HP RPM Voltage Frame Enclosure FL Amps (A) FL Eff (%) Approx. Wt. (lbs) IEEE1-18-143TC 1 1800 460 143TC TEFC 1.6 85.5 53 IEEE1.5-36-143TC 1.5 3600 460 143TC TEFC 2 84 53 IEEE1.5-18-145TC 1.5 1800 460 145TC TEFC 2.2 86.5 55 IEEE2-36-145TC 2 3600 460 145TC TEFC 2.6 85.5 55 IEEE2-18-145TC 2 1800 460 145TC TEFC 3 86.5 55 IEEE3-36-182TC 3 3600 460 182TC TEFC 3.8 86.5 90 IEEE3-18-182TC 3 1800 460 182TC TEFC 3.9 89.5 90 IEEE5-36-184TC 5 3600 460 184TC TEFC 6.1 88.5 105 IEEE5-18-184TC 5 1800 460 184TC TEFC 6.5 89.5 105 IEEE7.5-36-213TC 7.5 3600 460 213TC TEFC 9 89.5 150 IEEE7.5-18-213TC 7.5 1800 460 213TC TEFC 9.5 91.7 150 IEEE10-36-215TC 10 3600 460 215TC TEFC 12 90.2 165 IEEE10-18-215TC 10 1800 460 215TC TEFC 12.8 91.7 165 IEEE15-36-254TC 15 3600 460 254TC TEFC 16.9 91.7 260 IEEE15-18-254TC 15 1800 460 254TC TEFC 18.3 92.4 260 IEEE20-36-256TC 20 3600 460 256TC TEFC 23.1 91.7 300 IEEE20-18-256TC 20 1800 460 256TC TEFC 24.8 93 300 IEEE25-36-284TSC 25 3600 460 284TSC TEFC 28.5 91.7 380 IEEE25-18-284TC 25 1800 460 284TC TEFC 30.3 93.6 380 IEEE30-36-286TSC 30 3600 460 286TSC TEFC 33.8 91.7 410 IEEE30-18-286TC 30 1800 460 286TC TEFC 36 93.6 410 IEEE40-36-324TSC 40 3600 460 324TSC TEFC 45.5 92.4 550 IEEE40-18-324TC 40 1800 460 324TC TEFC 48.8 94.1 550 IEEE50-36-326TC 50 3600 460 326TSC TEFC 55.8 93 560 IEEE50-18-326TC 50 1800 460 326TC TEFC 59.9 94.5 560 IEEE60-18-364TC 60 1800 460 364TC TEFC 69.9 95 780 IEEE75-18-365TC 75 1800 460 365TC TEFC 85.1 95.4 820 IEEE100-18-405TC 100 1800 460 405TC TEFC 114.1 95.4 1110 -

White Epoxy Painted Features

• 1-100 HP

• 3600 and 1800 RPM

• Single voltage, 460 volt

• TEFC enclosure

• Dual rated service factor: 1.15 for 40°C / 1.0 for 65°C

• Class F insulation with Class N varnish

• C-face - Rigid base

• Full compliance with IEEE-841, version 2009

• Meets or exceeds EISA 2007 requirements defined in NEMA MG-1 table 12-12

• White epoxy paint

• Suitable for use in USDA inspected facilities

• Conforms to AWWA D102 Outside Coating Systems: #4 (OCS-4), #5 (OCS-5) and #6 (OCS-6)

• Acceptable for use in high performance architectural applications

• 5-year warranty

• Parker Hannifin ProTech IP66 labyrinth seals on both drive-end and opposite drive-end bearings

• CSA Certified for Class I, Division 2, Groups A, B, C, D

• Inverter duty, 10:1 CT / 1000:1 VT

• Inverter shield insulation and inverter grade magnet wire meets or exceeds NEMA MG-1 Part 31 for exceptional corona and transient protection

• Class B temperature rise

• IP55 degree of protection

• NEMA design B torque

• IEEE-841 motor test report supplied with each motor

• Please allow additional 5-7 business days delivery

• Suitable for 50 hz operation with 1.0 service factor (1-150 HP)

- Please consult your mdi rep for 200 HP and above -

White Epoxy Painted Technical Specifications

Model HP RPM Voltage Frame Enclosure FL Amps (A) FL Eff (%) Approx. Wt. (lbs) IEEE1-18-143TC-EPOXY 1 1800 460 143TC TEFC 1.6 85.5 53 IEEE1.5-36-143TC-EPOXY 1.5 3600 460 143TC TEFC 2 84 53 IEEE1.5-18-145TC-EPOXY 1.5 1800 460 145TC TEFC 2.2 86.5 55 IEEE2-36-145TC-EPOXY 2 3600 460 145TC TEFC 2.6 85.5 55 IEEE2-18-145TC-EPOXY 2 1800 460 145TC TEFC 3 86.5 55 IEEE3-36-182TC-EPOXY 3 3600 460 182TC TEFC 3.8 86.5 90 IEEE3-18-182TC-EPOXY 3 1800 460 182TC TEFC 3.9 89.5 90 IEEE5-36-184TC-EPOXY 5 3600 460 184TC TEFC 6.1 88.5 105 IEEE5-18-184TC-EPOXY 5 1800 460 184TC TEFC 6.5 89.5 105 IEEE7.5-36-213TC-EPOXY 7.5 3600 460 213TC TEFC 9 89.5 150 IEEE7.5-18-213TC-EPOXY 7.5 1800 460 213TC TEFC 9.5 91.7 150 IEEE10-36-215TC-EPOXY 10 3600 460 215TC TEFC 12 90.2 165 IEEE10-18-215TC-EPOXY 10 1800 460 215TC TEFC 12.8 91.7 165 IEEE15-36-254TC-EPOXY 15 3600 460 254TC TEFC 16.9 91.7 260 IEEE15-18-254TC-EPOXY 15 1800 460 254TC TEFC 18.3 92.4 260 IEEE20-36-256TC-EPOXY 20 3600 460 256TC TEFC 23.1 91.7 300 IEEE20-18-256TC-EPOXY 20 1800 460 256TC TEFC 24.8 93 300 IEEE25-36-284TSC-EPOXY 25 3600 460 284TSC TEFC 28.5 91.7 380 IEEE25-18-284TC-EPOXY 25 1800 460 284TC TEFC 30.3 93.6 380 IEEE30-36-286TSC-EPOXY 30 3600 460 286TSC TEFC 33.8 91.7 410 IEEE30-18-286TC-EPOXY 30 1800 460 286TC TEFC 36 93.6 410 IEEE40-36-324TSC-EPOXY 40 3600 460 324TSC TEFC 45.5 92.4 550 IEEE40-18-324TC-EPOXY 40 1800 460 324TC TEFC 48.8 94.1 550 IEEE50-36-326TC-EPOXY 50 3600 460 326TSC TEFC 55.8 93 560 IEEE50-18-326TC-EPOXY 50 1800 460 326TC TEFC 59.9 94.5 560 IEEE60-18-364TC-EPOXY 60 1800 460 364TC TEFC 69.9 95 780 IEEE75-18-365TC-EPOXY 75 1800 460 365TC TEFC 85.1 95.4 820 IEEE100-18-405TC-EPOXY 100 1800 460 405TC TEFC 114.1 95.4 1110